Chemical composition : SiO₂ AL2O3 CaO MgO K2O Na2O B2 O3

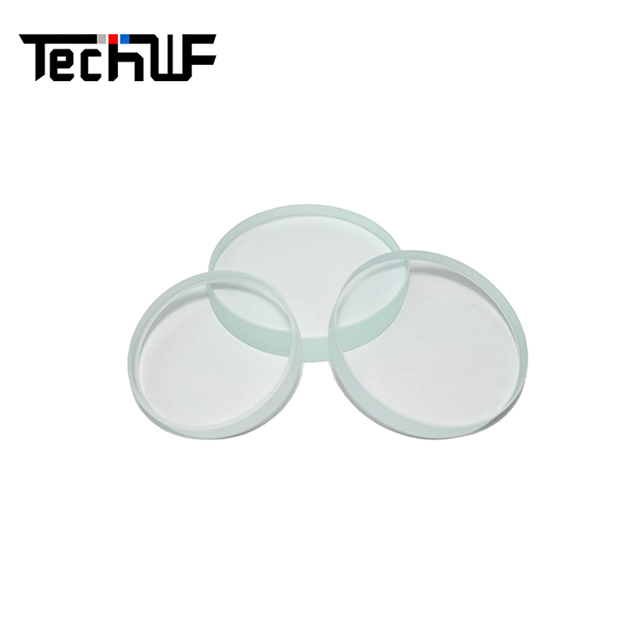

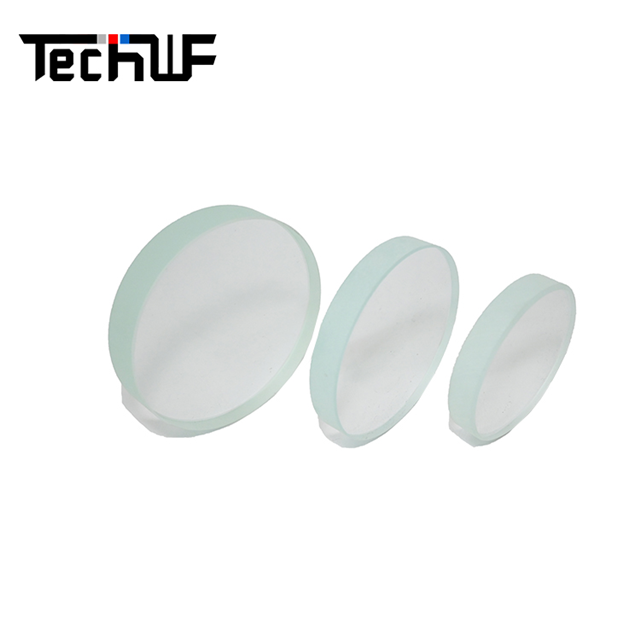

Product Description:

Mirrors generally refer to the observation (hole) of pressure vessels in chemical applications and instruments, and are used for supporting components such as chemical enamel equipment, light industry, refrigeration, printing and dyeing, shipbuilding, and explosion-proof equipment.

This product is made through processes such as cutting, billet making, grinding, polishing, edge grinding, quenching (tempering), etc. 2、 Product appearance quality indicators:

1. The color is colorless and transparent, with a slight hint of light green or yellow.

2. No dispersed small grooves, no alkaline bubbles or broken bubbles.

3. No filamentous or striped patterns.

4. No refractory sand, iron filings or other impurities, undissolved transparent crystals, and raw material white spots within 1cm ² Less than 2 in area and not on the surface or cracking.

5. There should be no more than two minor scratches with a length of less than 30mm outside the surrounding area of 15mm.

6. No cracks.

7. There are no pits or wrinkles on the two sealing surfaces, and there are no pits with a depth greater than 2mm on the side within 3mm of the chamfer diagonal. There are no wrinkles with a depth greater than 2mm on the entire side.

3、The physical and chemical performance indicators of the product meet the technical requirements of GB/T9963-1998 issued by the Ministry, and meet the requirements of GB23259-2009 Pressure Vessel Glass Mirrors

1. Bending strength: not less than 1550kgf/cm ²。

2. Temperature resistance: Temperature resistance ≤ 300 ℃,

3. Light transmittance: above. 90%.

4. Hydraulic water resistance strength: test. 25kgf/cm ² The intact rate is>95%.

5. Allowable temperature difference between inside and outside: ≤ 150 ℃

6. Linear expansion coefficient (0-300 ℃): 3.3 × 10 ° K

7. Softening temperature:>820 ℃

8. Annealing temperature: 450 ℃