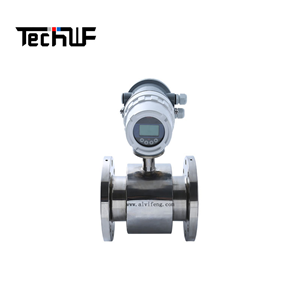

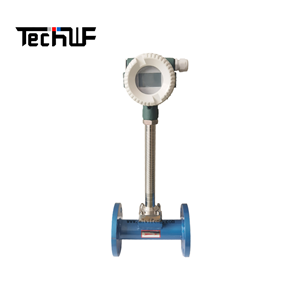

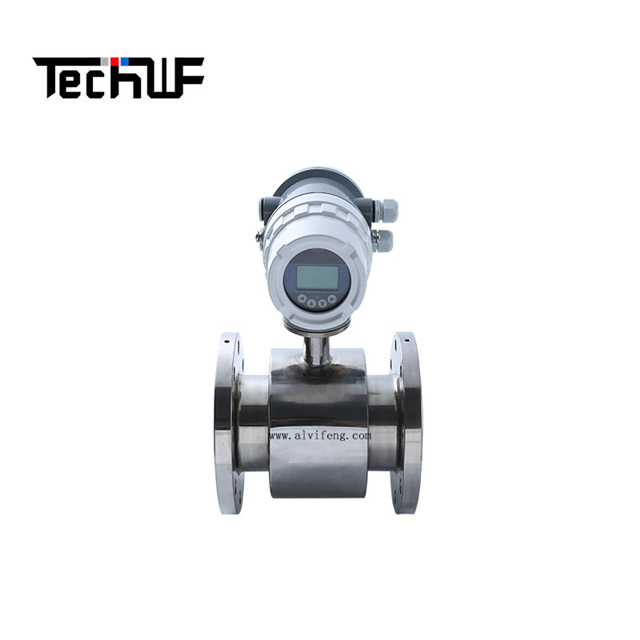

Electromagnetic Flowmeter

Working Principle

The electromagnetic flowmeter is manufactured with the latest electromagn

etic flow technology, and has the following characteristics:

1. The measurement is not affected by the change of fluid density, viscosity, temperature, pressure and conductivity;

2. There are no flow obstructing parts and pressure loss in the measuring pipe, and the requirements for straight pipe section are low;

3. Series nominal diameter DN4~DN3000.There are many choices for sensor lining and electrode materials;

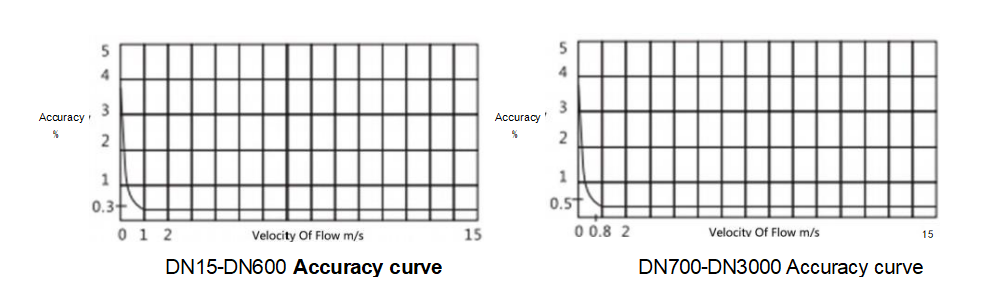

4. The converter adopts a novel excitation mode, with low power consumption, stable zero point and high accuracy. The flow range can reach 1500:1;

5. The converter can be integrated or split with the sensor;

6. The converter adopts 16 bit high-performance microprocessor, 2X16LCD display, convenient parameter setting and reliable programming;

7. The flowmeter is a two-way measurement system with three integrators: total forward, total reverse and total difference; It can display positive and negative flow, and has multiple outputs:

current, pulse, digital communication, HART, RS485 protocol;

8.The converter adopts surface mounting technology(SMT), with self inspection and self diagnosis functions;

9. Rubber and polyurethane lined sensors are intrinsically immersed;

10.Explosion proof instruments can be used in corresponding explosion-proof places;

11. Electromagnetic flowmeter is used to measure the volume flow of conductive liquid and slurry in closed

pipes, and is applicable to chemical industry,electric power, metallurgy, petroleum,water supply and drainage, paper making, medicine, food and other departments.

Parameter

Selection Of Lining Protection Flange And Grounding Flange

|

Flange Type |

Scope of application |

|

Grounding flange (grounding ring) |

Suitable for non-conductive pipes such as plastic pipes. However,sensors with PTFE lining are not required. |

|

Inlet protection flange |

When the medium has strong wear resistance,it is often used with polyurethane lining, but the lining is PTFE sensor unsuited. |