Pulse output, high linear characteristic accuracy, sensitiveresponse, wide flow range Signal output: pulse output (+12~+24VDC power supply, three wire system)Pulse output(+24VDC power supply, two-wire system) 4~20mADC analogcurrent explosion proof category of quantity signal output:Exdib mb IlBT6Gb, simple structure, installation easy to useand maintain, complete set of filter, degasser and straightening(flow) can be supplied a pair of companion auxiliary flangesfor installation can be provided (2 pieces)

Introduce

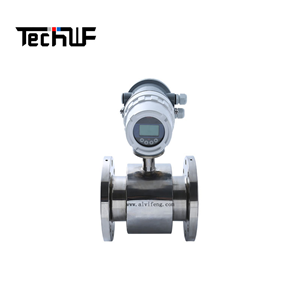

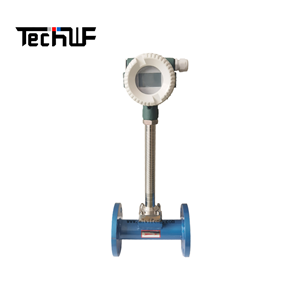

LWG turbine flow sensor and display instrument receiving electric pulse signal form turbine flowmeter, whichis used to measure low viscosity fluid (liquid or gas) in closed pipeline lt is widely used in petroleum, chemicalindustry, metallurgy, aviation, scientific research and other departments. The sensor consists of a turbine sensingassembly and an amplifier the structure assembled together is integrated: the structure that can measure thepositive and negative flow is bidirectional; The structure with insertion rod that can be installed in large-diameterpipeline to measure fluid flow is plug in type. The operation of the sensor is based on the principle of torquebalance. When the fluid flows through the sensor, the impeller is driven to rotate. When the flow rate is constantthe dynamic torque and resistance torque are balanced when the wheel speed is kept constant, the uniformlydistributed blades on the magnetized impeller rotate with the impeller, thus periodically changing themagnetoresistance of the detector (coil) magnetic field, and the detector generatesThe generating pulse signalis amplified by an amplifier and then output. The output electric pulse frequency is proportional to the impellerspeed and the impeller speed is proportional to the flow, so the output electric pulse frequency it is proportionalto the flow through the sensor, and the converted 4~20mA analog signal is also proportional to the flow.

Main Technical Data of Sensor

|

Dia DN |

Flow Range(m3/h) | Fluid temperature(℃) |

Mix Fluid Density (kg/m³) |

Pressure (MPa) |

Accuracy | |

| Integrated | Ex-Proof | |||||

| 15 | 4~16 |

-20~+55 -20~+120 |

-20~+70 | 0.6 | 1.6 | ±1.5% |

| 25 | 8~20 | |||||

| 40 | 20~100 |

2.5 6.3 |

||||

| 50 | 30~200 | |||||

Please Specify Requirements When Ordering

Please read this sample and understand the sensor model and coding regulations before ordering, andpropose the corresponding product model and coding according to your needs. lf necessary, Please alsoindicate

Fluid name, flow range, working pressure and temperature, viscosity, corrosivityEnvironmental conditions for product use (temperature, humidity, power fluctuation, electromagneticinterference, etc)

Please consult with our company for special requirements;Complete set selection: filter, degasser and rectifier.